Chenille machines are one of the special machines used in the production of chenille yarns, especially used in decorative textile products. Various parts that are subjected to intense wear and mechanical pressure during the production of chenille yarn are used in these machines. Spare parts are critical for the continuous and efficient operation of the machine. Here are the main spare parts used in chenille machines:

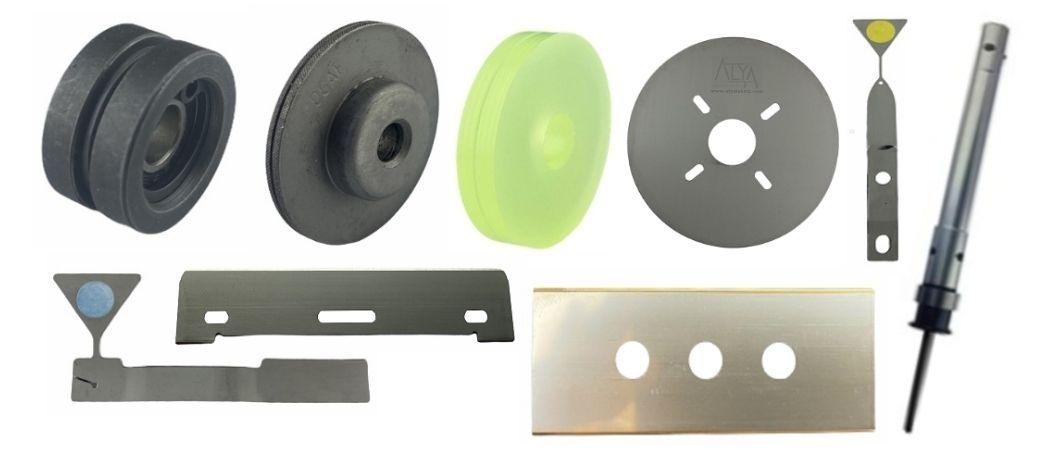

1. Needles (Chucks):

It is one of the most important components in chenille machines. The needles wind the thread and ensure that the fibers are twisted properly. Therefore, the needles are prone to wear due to overuse during production and should be replaced regularly.

2. Knives:

The knives used to cut the fibers of chenille yarn and hold them to the required length during the bending process require regular maintenance and replacement. When the blades are worn out, the cutting process will not be smooth and may affect the yarn quality.

3. Reel System:

The reels on which the yarns are wound control both the tension of the yarn and ensure smoothness during the winding process. The reels may wear out due to friction caused by the thread over time and may need to be replaced.

4. Cams:

Cams are mechanical components that correctly guide the moving parts of the machine. These parts coordinate the movement of the machine so that the chenille yarn is spun and wound properly.

5. Blood Pressure Adjustment Parts:

During the production of chenille yarn, the parts that adjust the tension of the yarn are very important. The slightest change in the blood pressure setting can lead to a deterioration in the quality of the thread. For this reason, these parts need to be checked regularly and the worn ones replaced.

6. Guides:

Guides that allow the yarn to follow the correct paths on the machine prevent the yarn from breaking or getting tangled. Since it can wear out over time due to friction, it is one of the parts that needs to be replaced regularly.

7. Bearings and Shaft Bearings:

Bearings and shaft bearings ensure the smooth operation of the rotating parts in the machine. These parts are in constant motion and can wear out over time, reducing the efficiency of the machine. Therefore, regular lubrication and replacement when necessary are important.

8. Electronic Control Units:

The electronic control units used in modern chenille machines ensure that the different functions of the machine work properly. When these units fail, the production process may be interrupted, and it is important to obtain spare parts quickly Jul.

9. Belts and Chains:

Belts and chains that transmit movement in machines play an important role during the production of chenille yarns. These parts may come loose or wear out over time, so regular checking and replacement is necessary if necessary.

Regular maintenance and replacement of chenille machine spare parts is critical in terms of efficient operation of the machine, high production quality and prevention of machine failures.

You Can Reach the Machine Blades by Clicking on Our Page